Product details

Product Overview

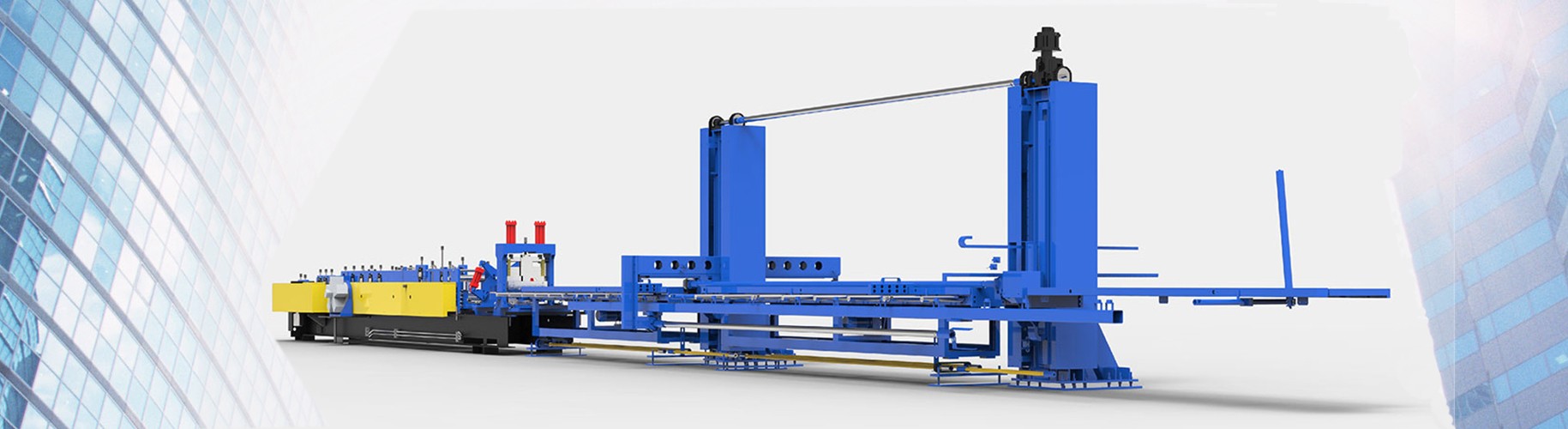

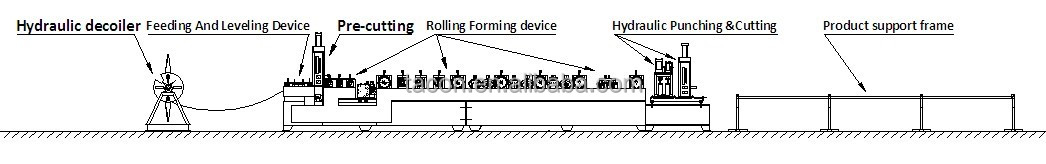

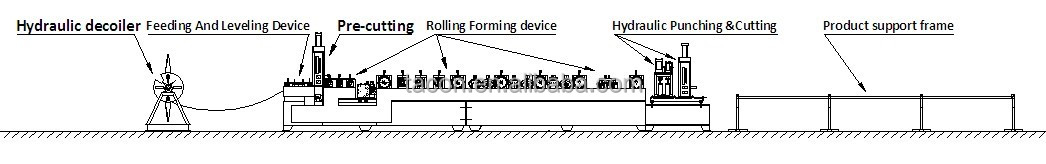

Our CL75-300 purlin machine consists of hydraulic decoiler,feeding and levelling device, pre-cutting, roll forming system,hydraulic punching and cutting,product support frame and PLC (controlling system).

FEATURES AT A GLANCE

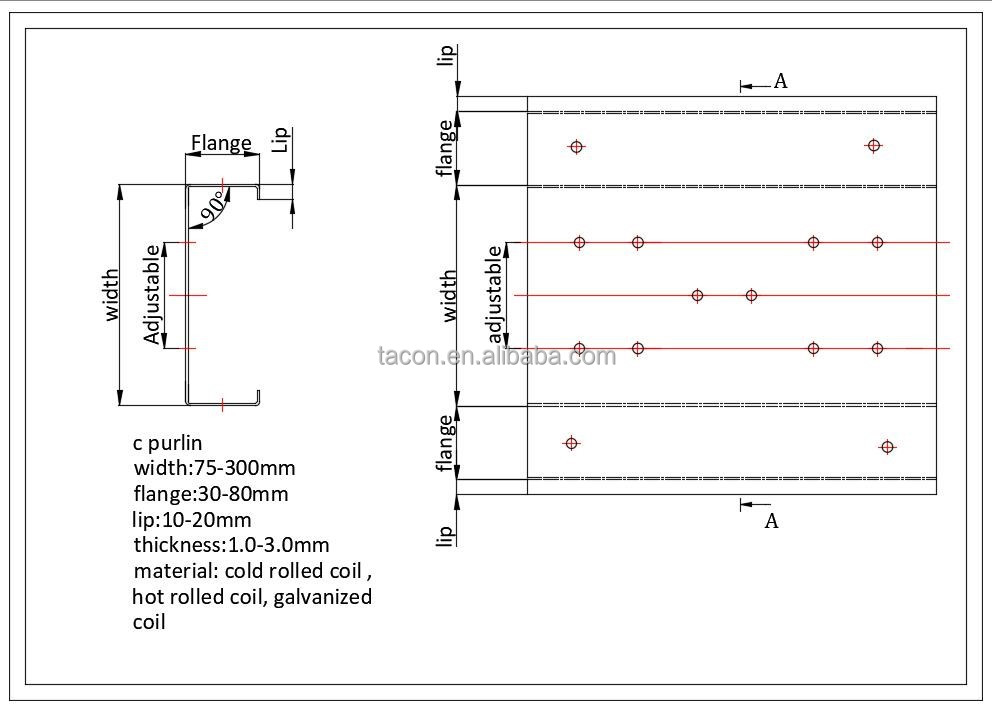

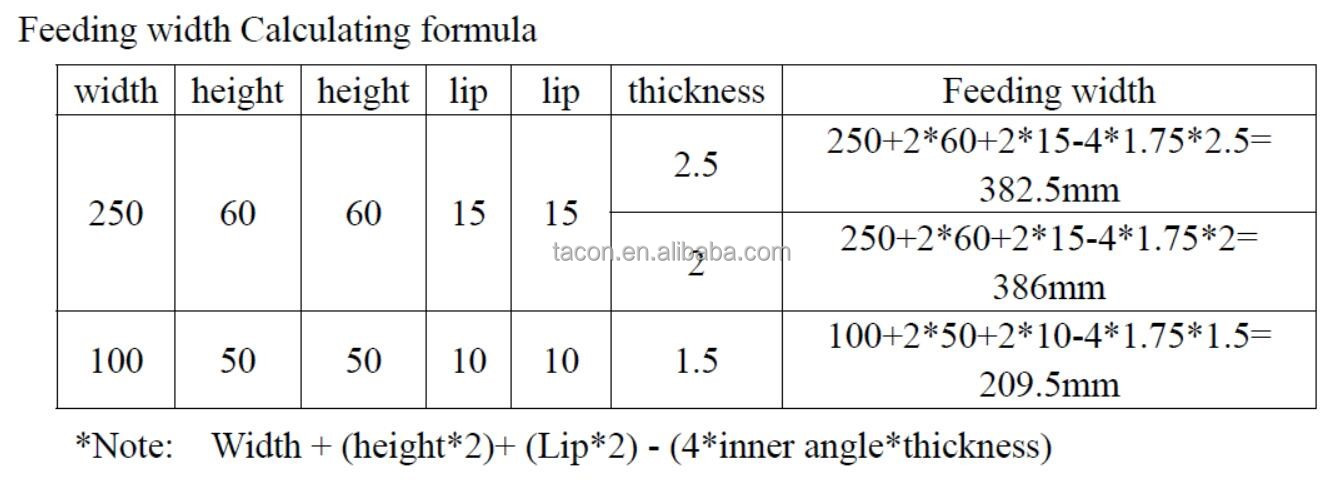

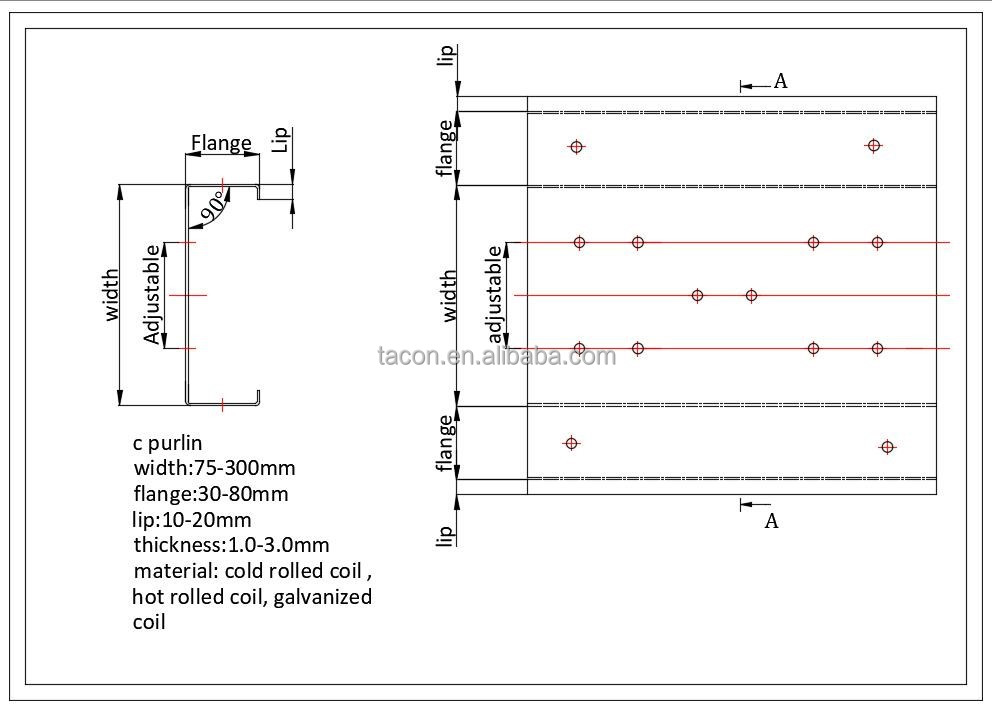

Profile Drawing

* Material:hot coil、galvanized coil

* Yield strength) :Q235Mpa Q345Mpa Q450Mpa

Flow Chart

Hydraulic decoiler→ Feeding and levelling→ Pre-cutting→ Roll forming machine→ Hydraulic punching and cutting→ product support frame

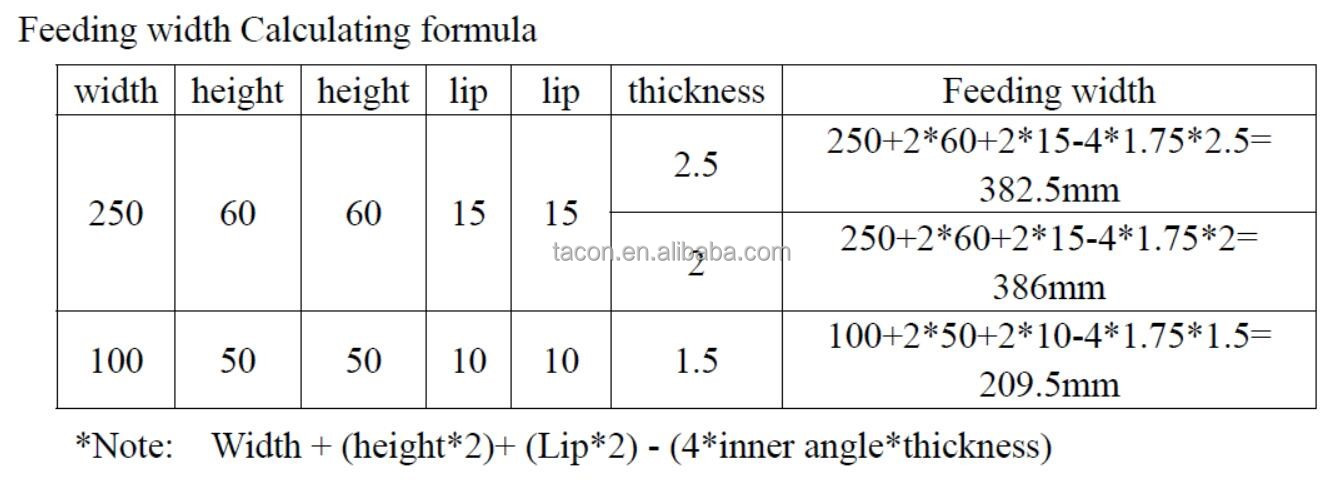

Technology Parameters

1.Decoiler

* Decoiler Type: Hydraulic decoiler

* weight capacity of decoiler : 6.0T

* diameter of inner: 350-580mm

* diameter of outer: 1200mm

* Decoiler will be with Coil Car

2.Feeding and Levelling

* Used for feeding and levelling before roll forming

* Feeding and guide rollers: 7 rollers up 3 down 4

3.Pre-cutting

It is used for change material or order finish cutting.

4.Roll Forming Machine

* Main motor type: Servo motor

* Motor power: 22KW

* Drive type: chain

* Roll speed: 10-22m/min

* Roller material: Cr12

* Change purlin size motor power: 2.25KW(0.75KW*3)

* Roller no.:16+1 (rib roller)

* main shaft material: 40Cr

* Main shaft diameter: ø75- ø93mm

* Changing sizes by computer

5.Hydraulic Post Cutting

* Cutting type: Hydraulic Post cutting

* Blade material: Cr12MoV

* Motor power:11KW

* Hydraulic pressure: 16Mpa

6.Product Support Frame

Product support frame: 6m

7.PLC Control System

* Voltage: 380V, 3 Phase 50HZ(according to your request)

* Plc sizes:700mmx1000mmx300mm

* PLC manufacturer: Japan panasonic

* Solenoid: YUKEN

* Cylinder: XINGDE

* Pipe: Omar

* Touch screen:Japan panasonic

* Encoder : Omron

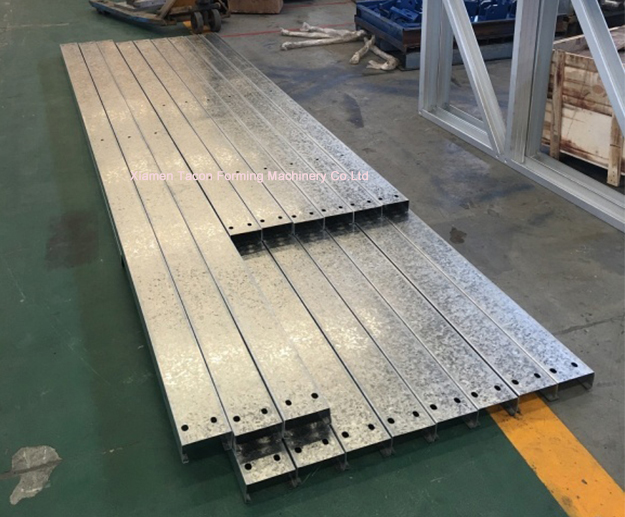

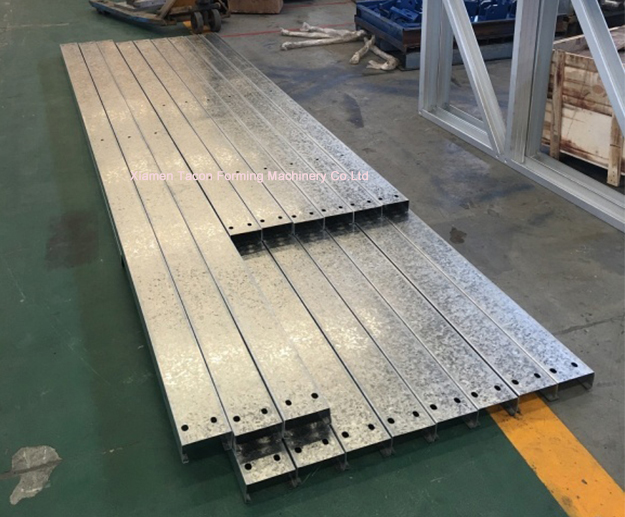

Successful Project